Modular Flexibility: Build Your Ideal Spindle

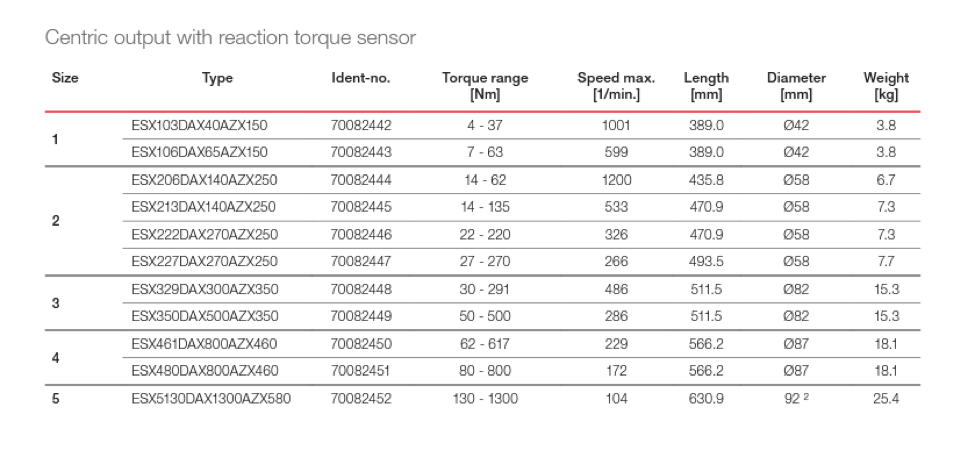

The ESX Fixtured Spindles shine with their adaptable design. Mix and match components like sensors and drives to tailor the spindle to your specific needs. No more wrestling with bulky cables – the innovative rotating joint hybrid plug lets you adjust the connection for perfect setup.

Streamlined Control: Say Goodbye to Cable Clutter

ESX spindles communicate digitally, minimizing wires and weight. Even with double-duty setups for both torque and angle measurement, you'll only need a single, thin, flexible cable for control and data. Enjoy smoother operation and reduced fatigue.

Maintenance on Demand: Work Smarter, Not Harder

Built-in maintenance management takes the guesswork out of upkeep. The tool schedules service based on actual usage, ensuring you only maintain it when it's truly needed. Save time and resources, and optimize your operations.

Unmatched Precision: Tighten with Confidence

AMT Fixture Spindles boasts the highest level of tightening accuracy. Action torque sensors directly at the output shaft ensure precise torque every time, unaffected by wear or drive conditions. Fasteners are secure, regardless of the tool's mechanical state.

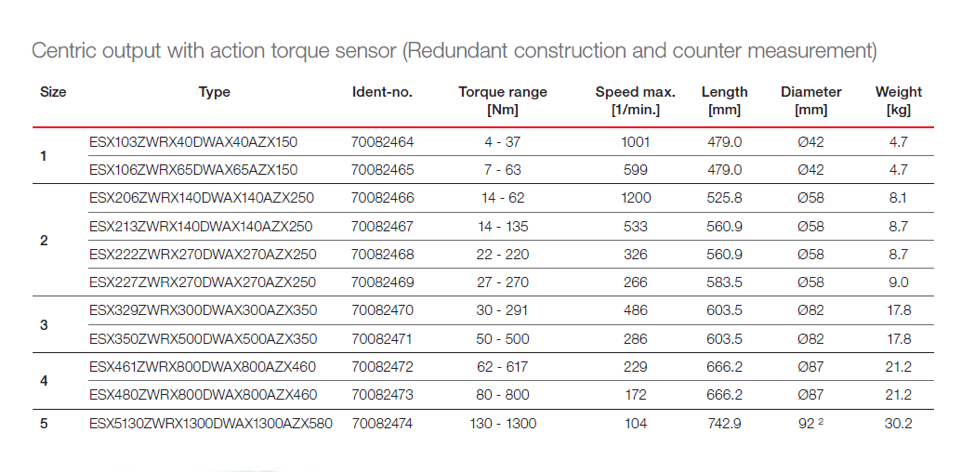

Enhanced Reliability: Redundant for Confidence

VDI Guideline 2862 recommends redundant sensors for critical connections. AMT spindles deliver. A control circuit monitors torque with an action sensor and angle transmitter, while a check circuit uses a reaction torque sensor and rotor bearing angle recording. This continuous monitoring allows for extended reference measurement intervals, maximizing efficiency without compromising accuracy.

After the sale, we are delighted to assist you with any technical concerns or inquiries. Don't hesitate—let's connect! Feel free to reach out to us via phone: 8282829795 or drop us an email at marketing@absgroup.in We're here to help and ensure your satisfaction.