Tools We Provide: A Comprehensive Range of Tensioners

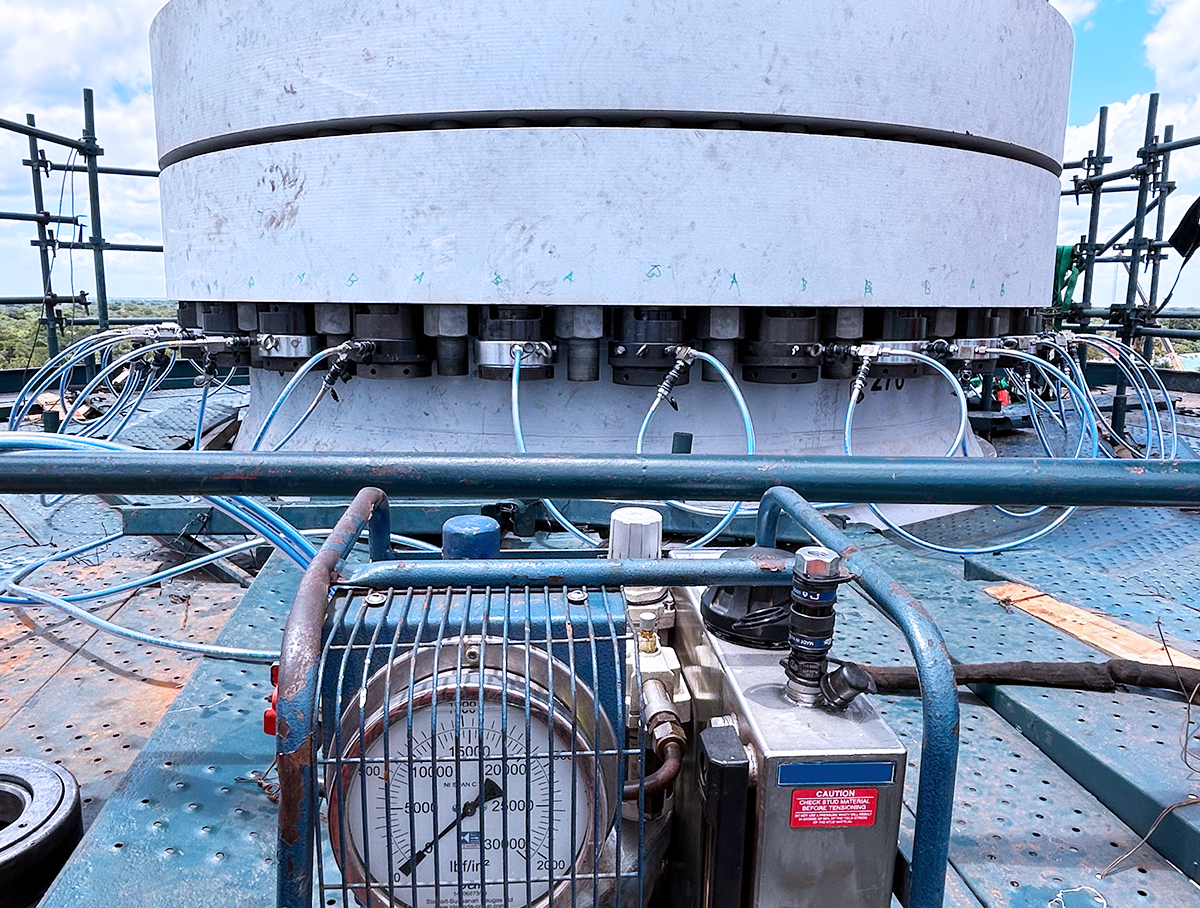

Standard Tensioners: Choose from our standard tensioners, ensuring reliability and performance in a variety of bolting applications.

Spring Return Tensioners: Experience the efficiency of our spring return tensioners, designed for optimal functionality and ease of use.

Foundation Tensioners: Meet your bolting requirements with our foundation tensioners, providing robust performance in critical projects.

Multistage Tensioners: Opt for versatility with our multistage tensioners, offering adaptability to different bolting scenarios.

Subsea Tensioners: Address underwater bolting challenges with our subsea tensioners, crafted for dependable performance in challenging environments.

About ABS Tensioning Tools

Diverse Range: Our comprehensive selection of tensioning tools caters to a variety of applications, ensuring a tool for every bolting need.

Adherence to Standards: Committed to quality, our tensioners conform to the stringent standards set by ANSI, API, and ASME, reflecting our dedication to precision and reliability.

Compatibility with Flanges: Our premium tensioners seamlessly integrate with all ANSI, API, and ASME flanges, providing versatility and adaptability in diverse projects.

Nut Handling Expertise: With the capability to handle nuts up to 4 inches, our tensioning tools showcase robust engineering, allowing for efficient and reliable bolting operations.

Tailored Solutions for Your Success:

Specific Requirements: We understand that each project is unique. That's why our tensioning solutions are tailored to meet your specific requirements, ensuring a perfect fit for your bolting needs.

Reliable Bolting Operations: Our precision tools are designed to deliver reliable and efficient bolting operations, contributing to the success of your projects.

Experience the pinnacle of bolting excellence with our precision tensioning tools. At ABS, we ensure quality meets adaptability for unparalleled performance in every project.

People Also Ask

ABS offers a diverse range of tensioners, including Standard Tensioners, Spring Return Tensioners, Foundation Tensioners, Multistage Tensioners, and Subsea Tensioners, each designed to cater to specific bolting needs.

ABS has a rich legacy spanning over 25 years, making it a trusted name in the bolting industry. The company has accumulated extensive expertise in precise tensioning over this period.

ABS is committed to providing unparalleled after-sales support, ensuring continuous assistance for projects. This support includes guidance on tool selection, as well as assistance with any issues that may arise during or after the bolting process.

ABS tensioners are known for dependable performance, top-tier quality with minimal instances of complaints, and a proven track record of consistently outperforming competitors in various projects, showcasing a commitment to excellence.

Customers can book a free demo with ABS to witness firsthand the exceptional performance and reliability of their tensioning tools.

Tensioning is crucial in various industries, including Oil and Gas (for drilling, refining, and transportation processes), Wind Energy (for the assembly and maintenance of wind turbines), Petrochemical (for construction and maintenance of plants), Construction (for structural elements, bridges, and high-rise buildings), and Nuclear (for maintaining the integrity of structures and components in power plants)

ABS tensioners adhere to stringent standards set by ANSI, API, and ASME, reflecting the company's dedication to precision and reliability.

ABS tensioning tools have the capability to handle nuts up to 4 inches, showcasing robust engineering for efficient and reliable bolting operations.

ABS understands that each project is unique, and their tensioning solutions are tailored to meet specific requirements, ensuring a perfect fit for diverse bolting needs.

ABS is a dedicated partner offering precision in every tensioning job, unmatched expertise, timely project completion, and support beyond supply. The company ensures that bolting tasks are efficiently executed, contributing to the success of projects.

Bolt tensioning ensures that bolts are uniformly tightened, providing even clamping force, which is essential for the integrity and performance of connections.

Bolt tensioning values are often calculated based on the desired preload and the bolt's characteristics, such as diameter and material. Specialized equipment like hydraulic tensioners may be used for precise control.

Bolt tensioning directly stretches the bolt to achieve the desired clamping force, while torquing relies on rotational force to achieve the same result.

Hydraulic tensioning involves using hydraulic equipment to apply a precise tension force to bolts, ensuring uniform preload.