Facing and Serration Range

Automated ID/OD Mount: 0” – 80”

Flange Serration Automatic: 0” – 80”

Manual Serration: 0” – 120”

Surface and Finish: 120 – 150 AARH

How Does It Benefit You?

Versatile Serration Options Enjoy the flexibility of choosing between automatic or manual serration based on your specific requirements. Our services offer a versatile approach to serration to cater to diverse project needs.

Reduced Manpower and Enhanced Safety Experience the advantage of reduced manpower requirements, coupled with a safer operational environment. Our approach prioritises safety, minimising the risks associated with manual labour.

Leak-Free Flanges Assurance Our services go beyond efficiency; they ensure the integrity of your connections. Experience leak-free flanges, contributing to the overall reliability and functionality of your piping systems.

Automated Tools for Efficiency Benefit from the efficiency of automated tools, which not only reduce job completion time but also consistently provide accurate results. The integration of automation enhances the precision and reliability of the entire process.

Key Applications

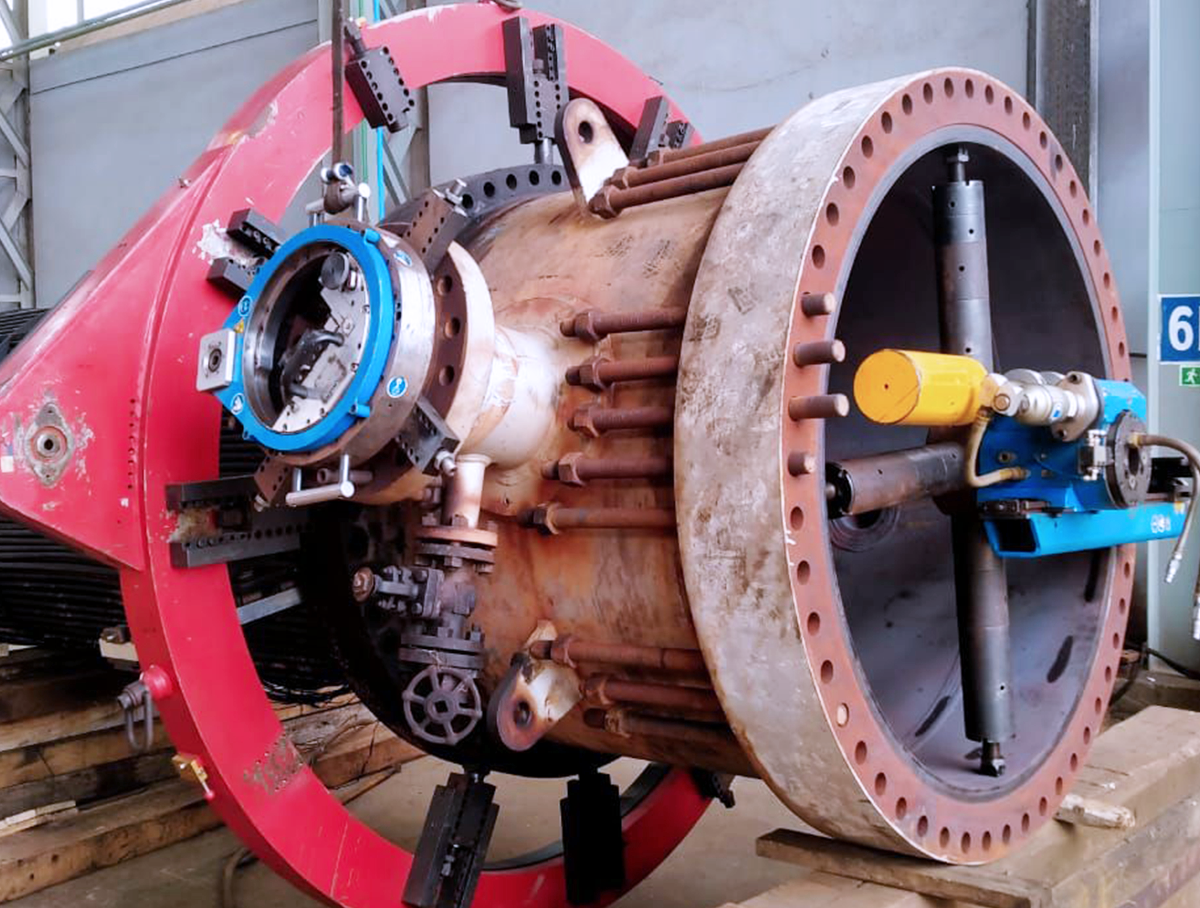

Re-facing Main Steam Inlet Flanges Precision services for the re-facing of main steam inlet flanges ensure optimal sealing and alignment. Our expertise in this application contributes to the efficiency and reliability of steam systems.

Facing and Beveling for Sealing and Weld Prep Our capabilities extend to the precise facing and beveling of pipes, catering to the critical requirements of sealing and weld preparation. This specialised service ensures a seamless and secure connection.

Repairing Piston Rod Mating Flanges We specialise in the repair of piston rod mating flanges, addressing wear and damage to ensure the proper functioning and longevity of machinery in various industrial applications.

Boiler Feed Pump Flanges Our services encompass the treatment and maintenance of boiler feed pump flanges, crucial components in steam systems. This includes precision-facing and beveling for optimal performance.

People Also Ask

Our automated ID/OD Mount services cover a range from 0” to 80”. The Flange Serration services are automatic within the same range, while manual serration extends up to 120”. Surface and finish services are provided in the range of 120 – 150 AARH.

Versatile Serration Options: Choose between automatic or manual serration based on your specific requirements.

Reduced Manpower and Enhanced Safety: Experience reduced manpower requirements with a safer operational environment.

Leak-Free Flanges Assurance: Ensure the integrity of your connections with leak-free flanges.

Automated Tools for Efficiency: Benefit from the efficiency of automated tools, providing accurate and timely results.

Customised Serration Solutions: Enjoy a range of serration options tailored to your project specifics.

Enhanced Operational Safety: Streamline operations and contribute to a safer working environment.

Long-Term Reliability: Experience assurance of leak-free flanges translating into long-term reliability.

Time and Cost Efficiency: Automated tools contribute to overall time and cost efficiency in project completion.

Our services cater to various applications, including re-facing main steam inlet flanges, facing and beveling for sealing and weld prep, repairing piston rod mating flanges, boiler feed pump flanges, re-machining gasket seals on tube sheets, repairing or cutting ring grooves, and plate and vessel weld prep.

Industry-Tailored Solutions: Our applications are designed to meet the specific needs of various industries, such as steam systems, machinery, and heat exchangers, ensuring optimal performance.

Comprehensive Maintenance Support: Our services go beyond individual applications, contributing to comprehensive maintenance support for various industrial components. This proactive approach enhances the longevity and reliability of critical systems.

Adherence to Industry Standards: We adhere to stringent industry standards in each application, ensuring that our services meet or exceed regulatory requirements. This commitment to quality and compliance underscores our dedication to excellence.

Our skilled onsite machining team offers portable flange facers capable of handling various sizes ranging from 0 to 120 inches (0 to 3048 mm). They can perform operations such as refacing, milling, beveling, squaring, counterboring, and machining weld prep or seal ring profiles for ID, OD, or surface mounting operations.

Flange maintenance is crucial as flanges can be damaged by turbulent flow, impacts from other components during construction, and various unavoidable factors. Proper maintenance ensures the longevity and reliability of flanges in industrial applications.

Serration on flanges enhances the seal between mating flanges by providing additional contact points, reducing the risk of leaks.

The depth of flange face serration depends on the flange type and specifications. It is usually designed to optimize the sealing surface.;

Flange serration can be visually inspected, and specialized tools may be used to measure the depth and ensure it meets the required standards.

Raised face (RF) is a common flange facing finish that provides a smooth sealing surface.